- Home Page

- Company Profile

-

Our Products

- Conveying System

- Pollution Control System

- Portable Dust Collector

- Venturi Scrubber

- Industrial Dust Extraction System

- Air Pollution Prevention Cyclone

- Dust Collection System

- Pollution Control Systems

- Bag Filtration System

- Dust Control Equipment

- Bag Filter Systems

- Dust Extraction System

- Cartridge Dust Collectors

- Fume Extraction System

- Pollution Control Scrubbers

- Air Pollution Scrubbers

- Industrial Mixers

- Industrial Dryers

- Filling Machine

- Hopper Bottom Silo

- Pneumatic Conveying System

- Bag Cage

- Mechanical Conveying Systems

- Storage Tanks

- Weighing System

- Linear Vibratory Feeder

- Dust Collector Parts

- Industrial Process Equipments

- Vibratory Equipment

- Grain Storage Products

- Pneumatic Linear Vibrators

- Dust Suppression

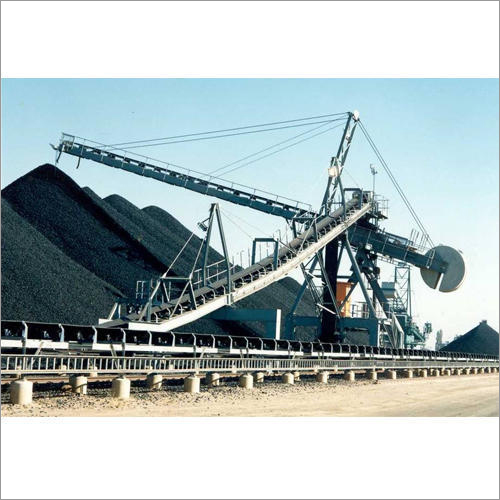

- Coal Handling Plants

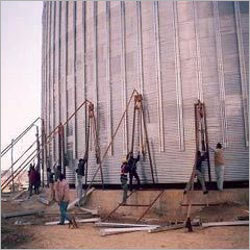

- Erection Services

- Vibratory Screen Separator

- Grain Bins

- Pressure Vessels

- Vibration Generator

- Vacuum Transfer System

- Industrial Fabrication

- Bag Unloading Station

- Contact Us

Showroom

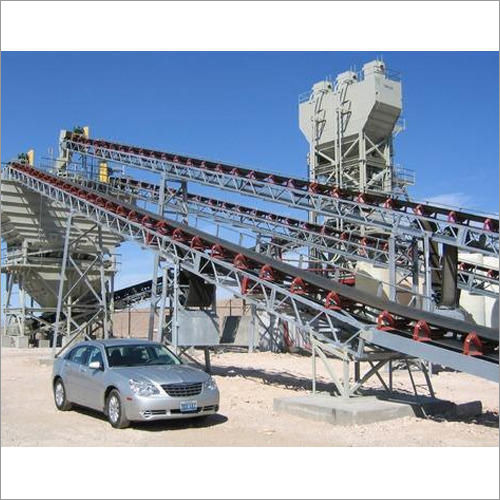

Use our superior quality Conveying Systems which are available in different designs, specifications, types, etc. These systems are used for handling heavy material. Also, they require less maintenance, have high strength and have robust designs.

We deal in wide range of Pollution Control Systems which are available in different types, specifications, designs, etc. They are ideal in processing units to maintain the parameters of the discharging air by removing the hazardous contaminants in an efficient manner.

We provide Industrial Mixers which are available in several designs and types. Besides, they are ideal for the continuous and homogeneous mixing of different kinds of materials irrespective of their physical state.

Industrial Dryers are heavy duty machineries for the sludge drying of various solid substances by efficiently removing the moisture and water content up to 30 to 40 percent. These are manufactured by using top grade materials which make them highly resistant to impacts of high temperatures.

Filling Machine are high performance automated systems that are especially designed for the food, pharmaceutical, nutraceutical and various industries to fill containers and plastic packets at a faster rate without any wastage which helps to increase the productivity.

Use our high grade quality Grain Storage Products which are available in different types, etc. Also, they are suitable for agricultural farms and grain processing units to ensure the safe storage of the grains.

Pneumatic Conveying System are industrial-class air-powered systems that are specially designed to transport lightweight free-flowing substances. There are many different types of these units availed by us that can be used in various industrial and construction plants.

We provide Bag Cage which are corrosion resistance and have superior finish. They are to provide a proper fitting space of the filter bags for ensuring proper sealing and longer bag life.

Our company deals in the manufacturing of a wide range of heavy-duty Mechanical Conveying Systems that are designed to lower labor costs, transportation time, and ensure the smooth movement of heavy materials within the industrial facility without the risk of accidents, and ensure the continuous supply of products at right place or time.

We are one of the best manufacturer and supplier of premium grade heavy duty Storage Tanks to store various types of raw and processed materials. These metallic containers are provided with galvanized surface coating to prevent corrosion and rust.

The offered range of Weighing System are electrical machineries that are used for the batching of various types of materials in calculated and proportioned manner. These are equipped with top quality electromechanical drives to give power to the system.

Linear Vibratory Feeder are industrial machineries that are used for the feeding of raw materials into the processing units of heavy machineries. These are manufactured by using top grade materials which make them sturdy and durable.

Dust Collector Parts are those parts that are used in collecting dust and filtering it. These parts collect dirt, dust, debris, gases, and chemicals from the air, delivering cleaner air to your facility, which has various advantages. They are very economical to use.

Industrial Process Equipment may be used for a variety of purposes such as storage, flow control, and chemical reaction containment. Each of these pieces of equipment is critical because it is required for the operation of a process. This is very effective to handle.

Vibratory Equipment is an instrument that employs vibration to adjust the rate of flow while feeding material through a process or machine. This has uses in food and chemical, rubber, foundry, processing, and other industries. This equipment is easy to use and safe to operate.

Grain Storage Products may help you avoid pollution, wasteful waste, and other costs. Proper food storage preserves the quality and nutritional content of the items you buy while also making the most of your food dollar by preventing spoiling. They are widely appreciated by our customers.

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free